Cruise Ship Propeller Cost

Advantages of multiple propellers.

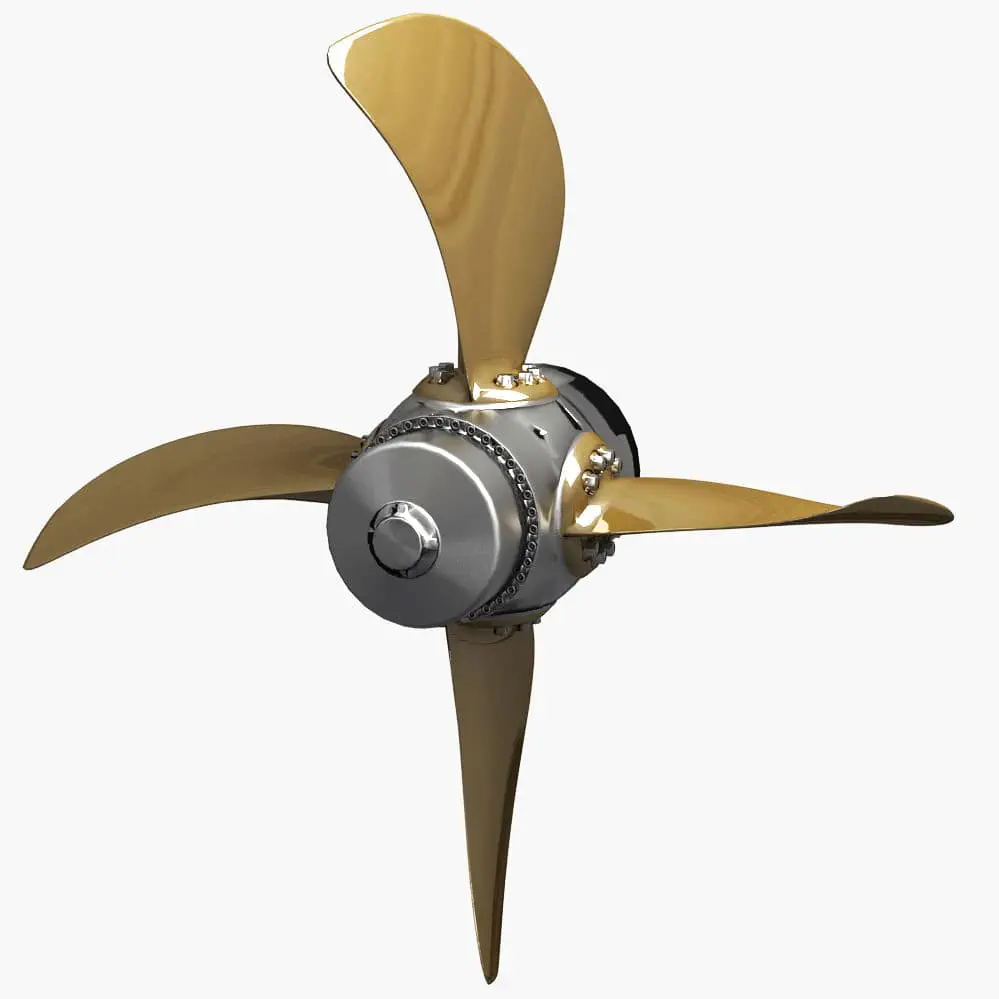

Cruise ship propeller cost. Manouvrability - with Azipods or similar and a small bow thruster is it possible to go alongside without tugs assisting. How Much Does a Cruise Ship Cost to Operate. Hurtigruten will install Promas Lite on their Richard With cruise ship in November this year.

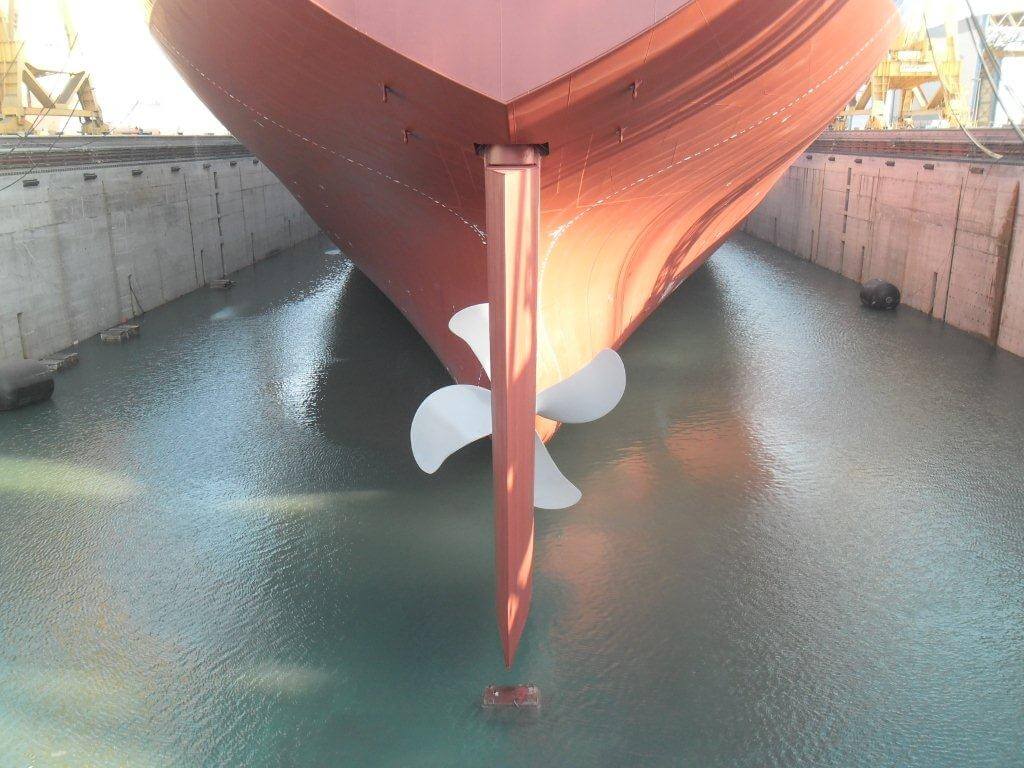

The pulling propeller eats from the homogenous field of water. Here are the basics on how a cruise ship is driven through the ocean. All cruise ships rely on propellers to push them through water.

The propeller positioning is optimized to the hull shape. All Propellers are Re-welded if required and then polished balanced re-tracked and Aluminium Propellers are re-painted. Seawise Giant was the longest ship ever built.

Fuel crew and maintenance are chief among the main culprits hogging the majority of costs. The annual operating expenses that follow are in a whole league of their own. The trials involved eight 17700 dwt vessels six of which were fitted with standard rudders and two with Energopac.

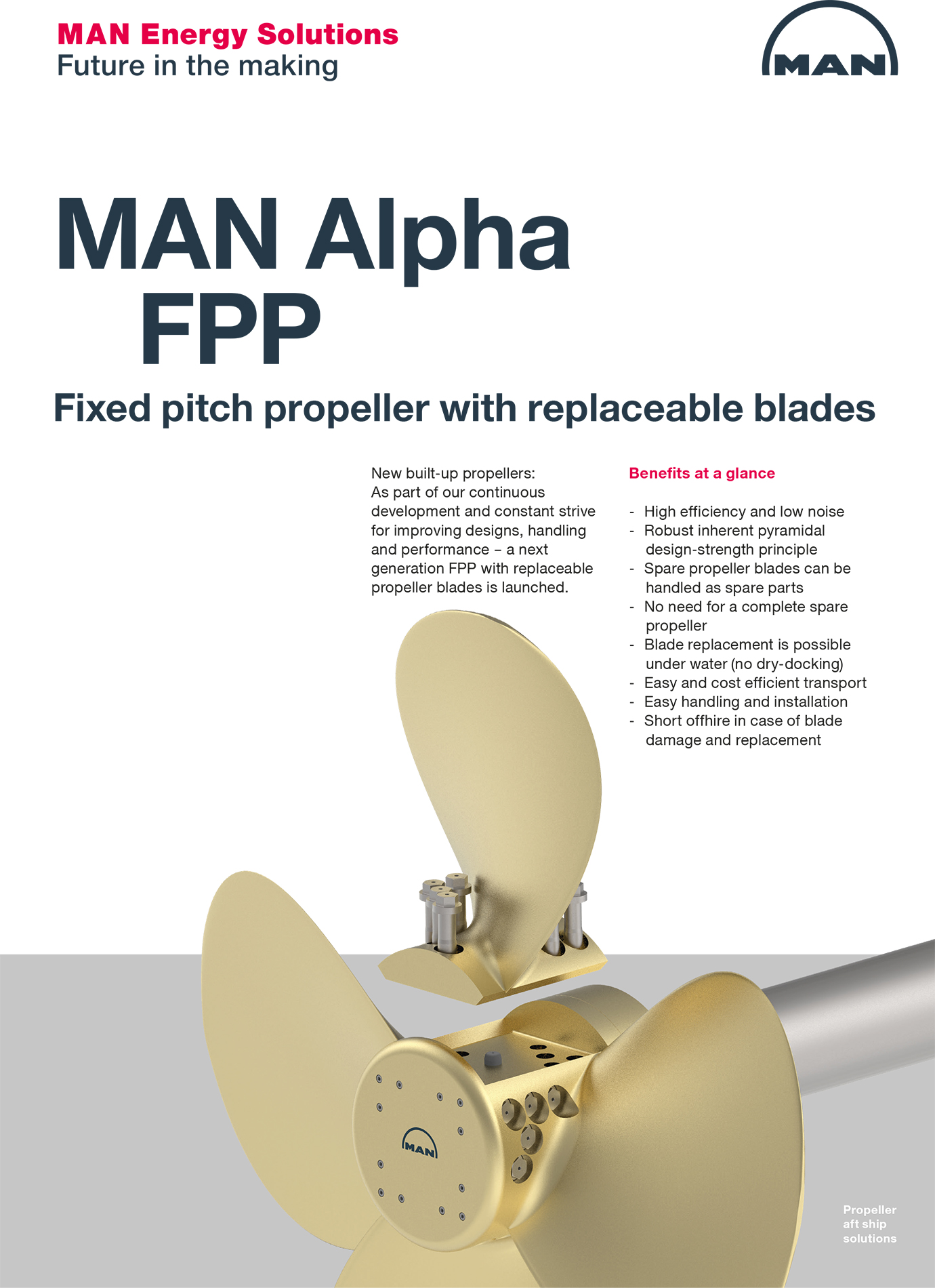

In this case the propeller is cast in one piece and is made of a complex. We can recondition Manganese bronze Aluminium bronze and Aluminium outboard and outdrive propellers. Lines price the cruise ships building cost by the number of beds the marine term is berths.

Economy - Azipod equipped vessels use less fuel. Who drives the ship. With the milestone of 5 million operational hours surpassed in 2009 Azipod today provides reliable cost-efficient service to a wide array of vessels and vessel types.